SWF Series

SWF Series

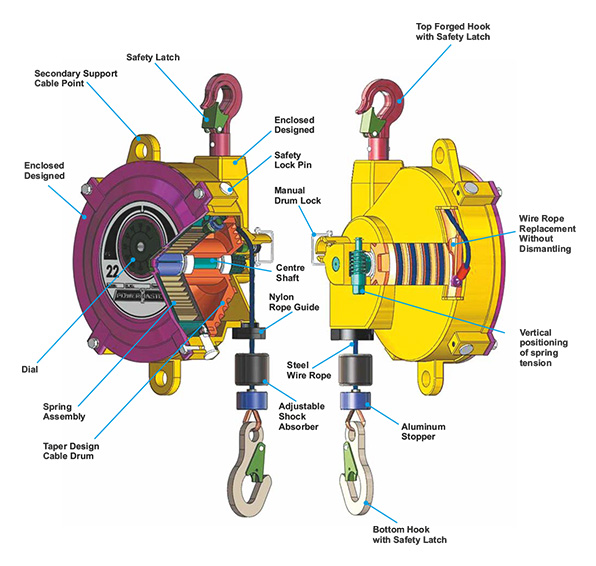

Standard Spring Balancers

SWF series balancers are now fully enclosed & are provisioned with a body liner to prevent damage to body.

| Capacity | 1.1 lbs to 440.8 lbs | 0.5 kg to 200.0 kg |

|---|---|---|

| Travel | 3.28 ft to 8.20 ft | 1.0 m to 2.5 m |

- Closed body and cover: Prevents industrial accident by preventing ingress of fingers inside the assembly.

- Body Liner: To prevent the wear of body by wire rope. Increases life of the balancer.

- Vertical axis Spring adjustment: This will facilitate adjustment of spring tension from ground level.

- Containerised Spring assembly: Concealed containers are easy in handling during maintenance and replacement of springs.

- Wire rope replacement without dismantling: A slot on balancer facilitates removal and installation of wire rope without disassembly of balancer. This facility is not available for long range balancer.

- Pressure die casting: Parts are manufactured through pressure die hence there is consistency in surface finish and total interchangeability of spares. Facilitates large batch production hence reduced delivery period.

- Safety lock pin: Locks drum pulley in the event of spring failure and thus prevents the fall of costly equipment & injury to the operator from falling load.

- Forged top hook: Permits 360 degree swivel of balancer.